Products

Our Products

Excavator Buckets (Range from 0.06cum – 2.6 cum)

PRN Engineers has gained immense expertise in supplying standard quality Excavator & Backhoe loader Buckets. These buckets are manufactured as per the set industry standards and norms using standard quality raw materials.

We create with the use of superior value raw materials and highly advanced machinery to manufacture these products as per the international standard and norms.

We also offer these products in various specifications in order to meet the diverse requirements of our respected customers in an efficient manner.

Counter weight extension for LR machines

A counterweight extension for LR machines is an additional weight that is added to the counterweight system of a lifting machine to increase its stability and improve its lifting capacity.

The extension helps balance the weight of the load being lifted, reducing the stress on the machine and reducing the risk of tipping or other safety issues.

Counterweight extensions can be added to a variety of lifting machines, including cranes, excavators, and other heavy machinery, and can be customized to meet the specific needs and requirements of each machine.

STP tanks of various tailor made sizes

Water tanks are containers used to store and hold water for various purposes, such as irrigation, fire suppression, drinking water, and industrial use. Water tanks come in a variety of sizes and shapes, including cylindrical, rectangular, and custom designs, and can be made of various materials, such as plastic, steel, concrete, or fiberglass. Some water tanks are designed for above-ground use, while others are designed for underground or partially buried use. The capacity of water tanks can range from a few gallons to several thousand gallons, and the selection of a water tank depends on the intended use and the volume of water required.

The selection of a water tank depends on specific requirements, such as the volume of water needed, the intended use, the location of the tank, and the environmental conditions.

Concrete Drum Assembly

A concrete mixer (often colloquially called a cement mixer) is a device that homogeneously combines cement, aggregates such as sand or gravel, and water to form concrete. A typical concrete mixer uses a revolving drum to mix the components. For smaller volume works, portable concrete mixers are often used so that the concrete can be made at the construction site, giving the workers ample time to use the concrete before it hardens.

An alternative to a machine is mixing concrete by hand. This is usually done in a wheelbarrow; however, several companies have recently begun to sell modified tarps for this purpose.

Self loading bucket for concrete drums

A self-loading bucket for a concrete drum is a type of attachment that can be added to a concrete mixer to facilitate the loading and mixing of concrete. The self-loading bucket typically consists of a hopper that can be filled with concrete components, such as sand, gravel, water, and cement.

The hopper can then be raised or tilted to dump the concrete into the drum of the mixer, where it is mixed by the mixer blades. The self-loading bucket can greatly speed up the concrete mixing process and reduce the need for manual labor in loading the concrete into the mixer. The attachment can be easily attached or detached from the mixer as needed.

Fuel tanks of various capacities for earth moving Equipments

Fuel tanks are containers designed to store and hold fuels, such as gasoline, diesel, or aviation fuel, for use in vehicles, engines, or other equipment. Fuel tanks can come in various sizes and shapes, depending on their intended use, and can be made of materials such as steel, aluminum, or plastic. They typically have a fill cap or opening to add fuel, and an outlet or nozzle to dispense fuel. Fuel tanks can be located in different parts of a vehicle or machine, such as under the hood, in the trunk, or in a remote location. Some fuel tanks also have features such as fuel gauges, filters, and vents to prevent overfilling and ensure safe operation. The selection of a fuel tank depends on factors such as the type of fuel being stored, the equipment it will be used in, the location of the tank, and the amount of fuel needed for the intended use.

Hydraulic tanks of various capacities for earth moving Equipments

Hydraulic tanks are containers used to store and hold hydraulic fluid, such as oil or water-based fluids, in hydraulic systems. These systems are used in construction and earth-moving equipment, as well as in other industrial machinery, to transfer and apply power using pressurized fluid.

Hydraulic tanks are designed to meet the specific requirements of the hydraulic system, including the volume of fluid needed, the operating pressure, and the operating temperature. The tanks can be made of various materials, such as steel, aluminum, or plastic, and can come in a variety of shapes, such as cylindrical, rectangular, or custom-designed.

Booms & Sticks of various sizes for earth moving Equipments

Boom and stick refer to the long arms or extensions on construction and earth-moving equipment, such as excavators, cranes, and backhoes.

Together, the boom and stick provide a versatile and flexible mechanism for moving and manipulating materials and objects. Different types of booms and sticks are available for specific applications, such as digging, grading, and demolition.

The selection of booms and sticks depends on the size and weight of the tool, the reach and depth required for the job, and the power and capacity of the machine.

Sheet metal press parts & subassemblies like Fenders, Supports, covers etc

Sheet metal press parts and subassemblies refer to components that are manufactured by pressing sheets of metal into a desired shape or form. Some examples of these parts and subassemblies include fenders, supports, covers, and other similar components used in various industries.

The process of making these parts and subassemblies involves using a press machine, which exerts high force on the metal sheet, molding it into the desired shape. The metal sheet can be made of various materials, including steel, aluminum, and others, depending on the application requirements.

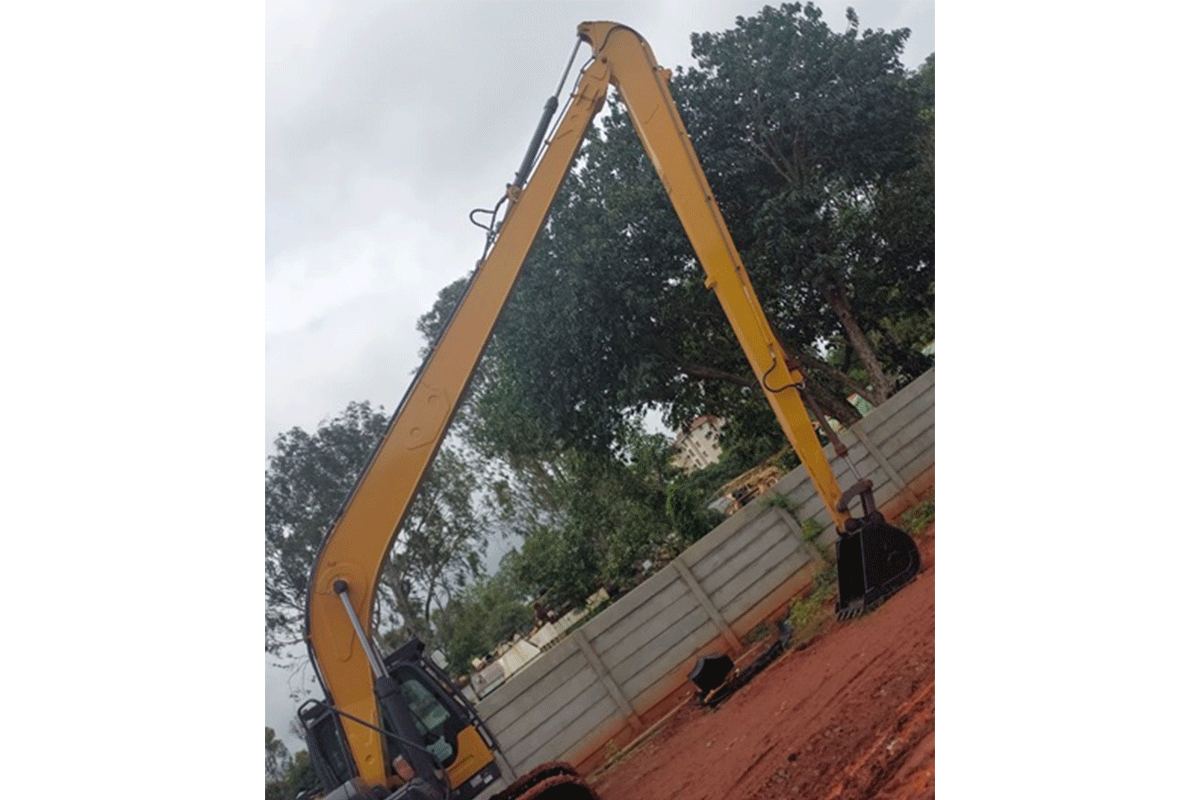

Long Reach Boom Assemblies

Long reach boom assemblies are specialized attachments for excavators designed to extend their reach, allowing access to distant or elevated areas. They consist of multiple segments, including a base, middle section, and extended end, operated via hydraulic systems for precise movement and control. Made from high-strength steel or alloy, these assemblies are crucial in construction, demolition, and mining for tasks that require extended reach without repositioning the entire machine. They improve versatility and efficiency but can affect machine stability and load capacity, necessitating careful consideration and regular maintenance to ensure safe and effective operation.

Bogie Frame Arrangement for Indian Railways

The bogie frame arrangement for Indian Railways is a critical component in railway rolling stock, providing structural support and stability for train carriages. Typically, the bogie frame consists of a robust, welded steel structure with integral axle boxes, suspension systems, and wheelsets. It supports the weight of the carriage and facilitates smooth movement over tracks by absorbing shocks and vibrations. The design includes provisions for integrating braking systems and allows for the necessary lateral and vertical movements. This arrangement ensures safe, reliable, and efficient operation of trains, contributing to the overall performance and safety of the railway network.