Machineries & Facilities

Machineries & Facilities

CNC Plasma (Make Messer) /Oxy flame cutting machine – Cap 5-300mm thick,4000 x 16000 mm

CNC plasma cutting and oxy-fuel cutting machines are two different types of industrial cutting machines used to cut and shape various materials such as metal sheets, pipes, and plates.

CNC plasma cutting machines use a plasma torch that generates a high-velocity jet of ionized gas to melt and cut through the material. The plasma torch is attached to a computer-controlled cutting table, which moves the torch around to create the desired shapes and cuts. CNC plasma cutting machines are often used for the precision cutting of thin and thick metal sheets.

Heavy duty lathe – 7Ft with 80mm Spindle bore

A heavy-duty lathe with a 7ft length and 80mm spindle bore would be a large and powerful machine used for machining large, heavy workpieces. The spindle bore diameter of 80mm is quite large, which would allow for the machining of large-diameter stock and the use of large-diameter tooling.

Overall, a heavy-duty lathe with a 7ft length and 80mm spindle bore would be suitable for machining large, heavy workpieces such as shafts, rollers, and other cylindrical components. It would be commonly used in industries such as oil and gas, aerospace, and heavy machinery manufacturing.

Air Compressor – 20 HP

An air compressor with a 20 horsepower (HP) motor is a powerful machine that is designed to provide a high volume of compressed air for industrial and commercial applications. The motor is the component that drives the compressor, and a 20 HP motor is typically quite powerful and can deliver significant compressed air output.

Air compressors with a 20 HP motor are suitable for a wide range of applications, including automotive, manufacturing, and construction. They can be used for tasks such as powering air tools, inflating tires, and painting. They may also be used for more heavy-duty applications, such as powering pneumatic machinery and equipment.

Independent power transformer of 500 KVA

A power transformer of 500 KVA (kilovolt-ampere) is a transformer with a power rating of 500,000 VA (volt-amperes) or 500 kW (kilowatts). Transformers are electrical devices that transfer electrical energy from one circuit to another by means of electromagnetic induction.

In power systems, transformers are used to step up or step down the voltage of the electrical power transmitted from the power generating station to the end users. The 500 KVA transformer would typically be used to step down high-voltage power from the transmission system to a lower voltage suitable for distribution to homes, businesses, and industrial facilities.

Double Girder EOT Crane of 10 T Cap For Material Handling

A double girder EOT (Electric Overhead Traveling) crane with a 10-ton capacity is a heavy-duty material handling machine designed to move heavy loads within a workshop, warehouse, or manufacturing facility. The crane is made up of two overhead beams or girders, which are mounted on rails and supported by columns. The trolley and hoist are mounted on the two girders, allowing the crane to move heavy loads along the length of the rails.

The 10-ton capacity of the crane refers to the maximum weight of the load that the crane can lift and move. This makes the crane suitable for handling heavy loads, such as large machinery or equipment, steel beams, or building materials.

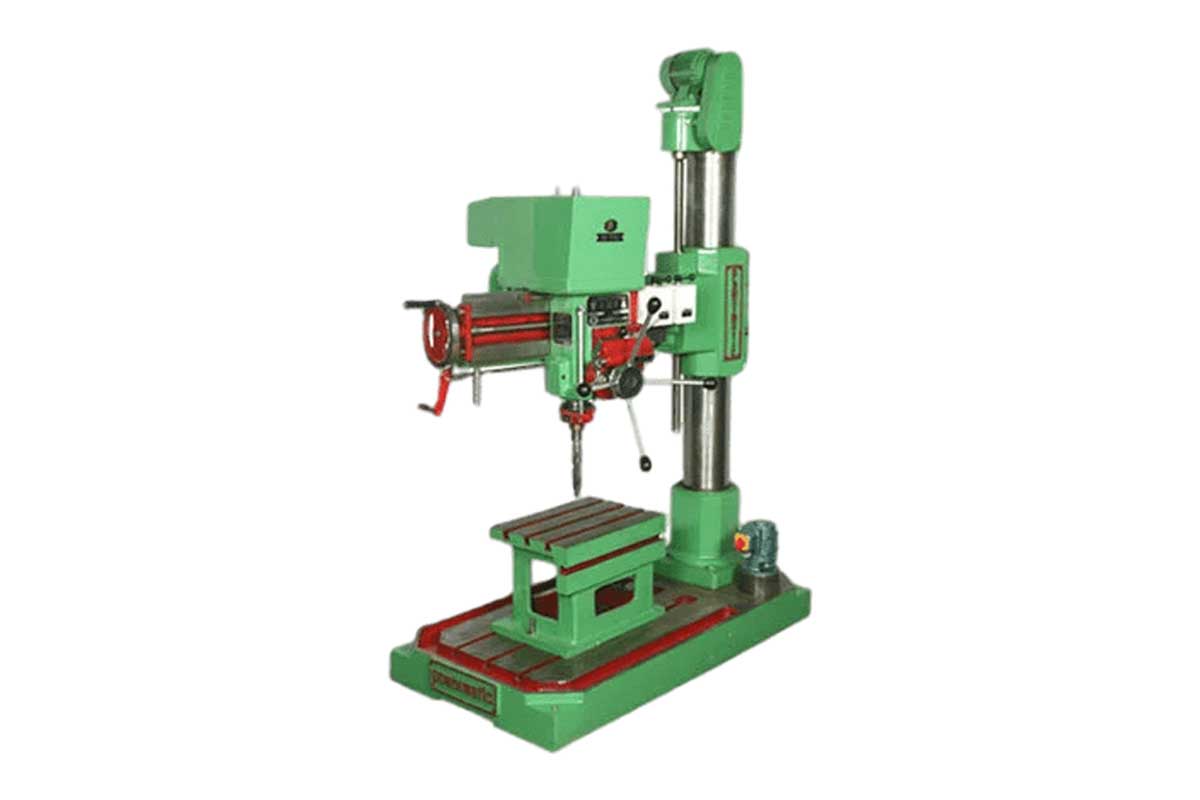

RM 38 Radial drilling machines

RM 38 Radial drilling machines are industrial machines used for drilling holes in a variety of materials, including metal, wood, and plastic. The machines are designed with a radial arm that can be moved in and out, up and down, and rotated around a vertical column, allowing for the drilling of holes at different angles and positions.

The machine is operated by an electric motor that drives the drill spindle, which is mounted on the radial arm. The radial arm can be adjusted to the desired angle, allowing the drill to be positioned precisely over the workpiece. The machine also includes a clamping mechanism to hold the workpiece in place while drilling. Overall, the RM 38 Radial drilling machine is a versatile and reliable tool that can be used for a variety of drilling applications, making it a valuable addition to any industrial operation.

Sophisticated Painting booths with oven & hoists

Sophisticated painting booths with ovens and hoists are specialized facilities that are used for painting large objects such as cars, trucks, aircraft, and industrial equipment. These booths are designed to provide a controlled environment for painting, with features such as temperature and humidity control, filtration systems, and exhaust systems to remove fumes and overspray.

The ovens in these booths are used to cure the paint and coatings applied to the objects being painted. The curing process is essential to ensure the paint is durable and long-lasting. The hoists in the booths are used to move the objects being painted, allowing for easy access to all areas of the object.

Sophisticated painting booths with ovens and hoists are typically used in industrial settings where large objects need to be painted quickly and efficiently.

Heavy Duty Automatic Band Saw

A heavy-duty, automatic band saw is a large, powerful machine that is designed to cut through a wide range of materials quickly and efficiently. These machines use a continuous band saw blade, which is guided by wheels and driven by a motor. The blade is typically made from high-speed steel or carbide, and is designed to withstand high temperatures and stresses generated during cutting.

Automatic band saws can be programmed to make precise cuts automatically, reducing the need for operator intervention. They can be used for a wide range of applications, including cutting metal, wood, plastics, and other materials.

Heavy-duty automatic band saws are typically larger than standard models, with a higher horsepower motor and a larger blade. They may also have a larger cutting capacity, allowing them to cut through thicker materials.

CNC Hydraulic Press brake – 325T, Cap 13 x 4000 mm

A CNC (Computer Numerical Control) hydraulic press brake is a type of industrial machine used for bending and forming metal sheets, plates, and other materials. The machine is controlled by a computer program that directs the movement of the hydraulic ram and the positioning of the workpiece, allowing for precise and repeatable bending operations.

The press brake consists of a flat table, where the workpiece is placed, and a hydraulic ram that presses the workpiece against a die, creating a bend. The hydraulic system provides the force necessary for bending, while the CNC system controls the position and movement of the ram.

The CNC hydraulic press brake is ideal for creating precise and complex bends, such as those required in the automotive industries. The machine allows for the creation of consistent and accurate bends, reducing errors and increasing efficiency.

MIG welding machines – 400A & 500A

MIG (Metal Inert Gas) welding machines are industrial machines used for joining metal parts together using an electric arc and a consumable wire electrode. The wire electrode is fed through a welding gun, which also dispenses an inert gas, such as argon or helium, that shields the weld area from atmospheric contamination.

MIG welding machines can be operated in a variety of settings, including manual, semi-automatic, and automatic. The machines are typically used for welding mild steel, stainless steel, and aluminum, and can be used in a variety of industries, including manufacturing, automotive, construction, and more.

MIG welding machines are known for their versatility, as they can be used for both thin and thick materials, and can create high-quality welds with minimal splatter or slag. They are also known for their speed and efficiency, allowing for fast and cost-effective welding operations.

3 Roll Pyramid type, NC, Hydraulic Rolling machine – Cap 13 x 4000 mm

A 3-roll pyramid type, NC (numerically controlled), the hydraulic rolling machine is an industrial machine used for bending and shaping metal sheets, plates, and other materials. The machine is designed to create cylindrical shapes or cones by passing the material through three rollers that apply pressure and force the material to bend and shape around the rollers.

The top roller can move up and down to adjust the position and pressure of the bending force on the material, while the bottom rollers rotate in opposite directions, pulling the material through the machine.

The NC or numerically controlled aspect of the machine allows for precise control over the bending process, with the operator programming specific dimensions and angles for the final product. The hydraulic system provides the force necessary to bend the material, with the amount of force controlled by the NC system.

The benefits of using a 3-roll pyramid type, NC, hydraulic rolling machine include faster production times, increased accuracy, and improved consistency in the final product.

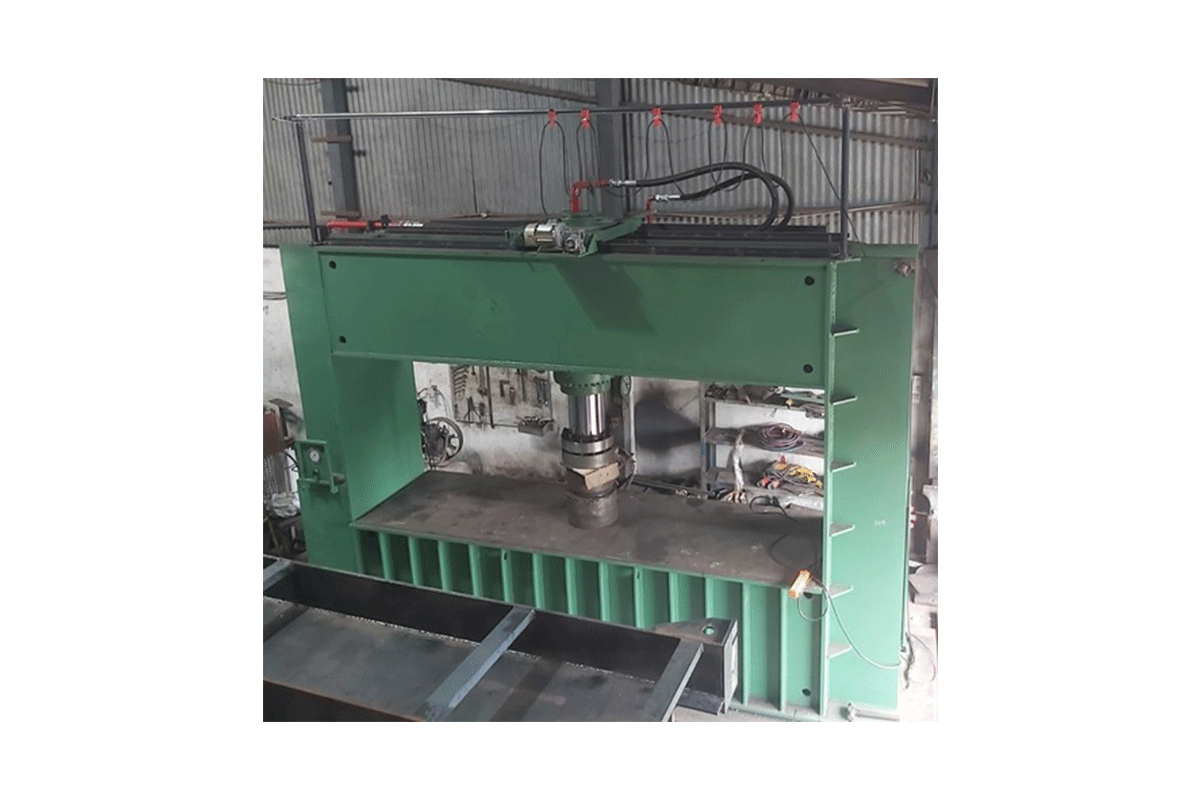

Hydraulic Press

A hydraulic press is a machine that uses hydraulic force to compress, shape, or mold materials. It operates based on Pascal’s principle, where a small force applied to a smaller piston generates a larger force on a larger piston. The press typically consists of a robust frame, a hydraulic cylinder, and a ram that applies pressure to the material. It is widely used in manufacturing for tasks such as metal forming, molding plastic, and creating intricate parts. Hydraulic presses are valued for their ability to deliver high pressure with precision, making them essential in industries like automotive, aerospace, and metalworking.

Shot Blasting

Shot blasting is a surface finishing process that involves propelling abrasive particles, or “shots,” at high velocity onto a material’s surface to clean, strengthen, or improve its texture. This technique is commonly used to remove rust, scale, and old paint from metal surfaces, as well as to prepare surfaces for coating. The process involves a shot blasting machine with a blast wheel or nozzle that directs the abrasive material onto the target surface. Shot blasting enhances surface durability, improves adhesion for coatings, and can also be used to achieve specific surface finishes. It is widely utilized in industries such as automotive, aerospace, and construction.

Horizontal Boring Machine

A horizontal boring machine is a versatile tool used for precise machining of large, heavy workpieces. It features a horizontal spindle, which holds the cutting tool, allowing for accurate boring, drilling, milling, and facing operations. The machine is ideal for enlarging holes or creating complex geometries in materials like metal or wood. Workpieces are typically mounted on a stationary table, while the spindle moves horizontally. Horizontal boring machines are widely used in industries like aerospace, automotive, and heavy machinery manufacturing due to their ability to handle large, cumbersome parts with high precision and stability.

State of the art QA Lab Equipment

The QA-Inspection & Laboratory is equipped with latest testing M/C for, Mechanical and Chemical properties of metals. Also, The lab is equipped with layout inspection procedures to inspect CTQ Parameters using latest Digital Measuring Instruments

Spectrometer

Specifications

- MOSS Optical Emission Spectrometer (With CRM)

- Fully digital pulsed current-controlled source for plasma generation

- Site-upgradable to add bases/matrices/elements

- Advanced Argon Saver

- In-built safety and diagnostics systems

- The Analyst user-friendly software suite

- Setting-up Samples (SUS) included Calibrations Included: Fe Base: MS/CS/LAS, Cr Ni Steel.

- 16 element analysis of metals.

Universal Testing Machine

Specifications

- Computerized Universal Testing Machine.

- With standard leaflet.

- Make : FSA, Model, TUE-C-600.

- Thickness from 1 – 32mm.

Hardness Testing Machine

Specifications

- Vickers Hardness Testing Machine.

- With standard leaflet.

- Make : BIE, Model, BV-50.

- Load in KGF- 10,15, 15.625,

20,30,31.25, 40, 50.

Specifications

- Vickers Hardness Testing Machine.

- With standard leaflet.

- Make : BIE, Model, BV-50.

- Load in KGF- 10,15, 15.625,

20,30,31.25, 40, 50.

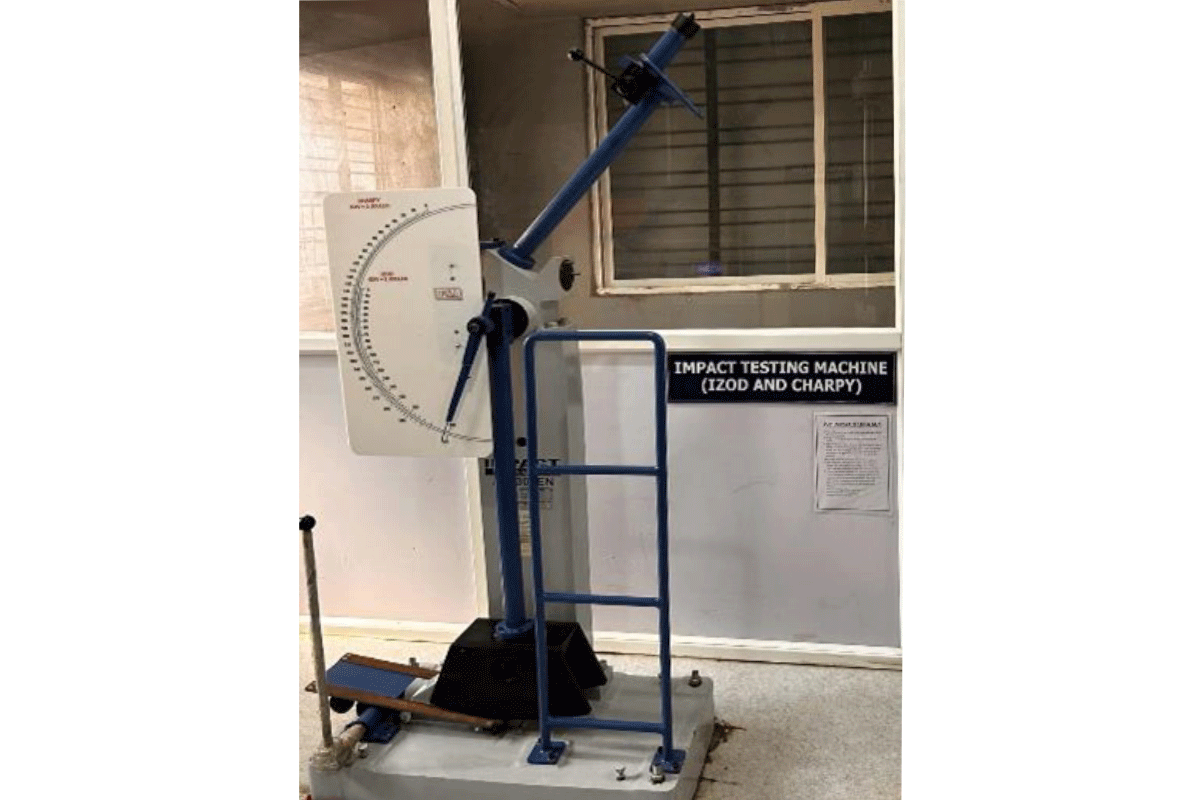

Impact Testing Machine

Specifications

- Izod & Charpy Impact Testing Machine(European Standard & IS).

- With standard leaflet.

- Make : FSA, Model, AIT-300 EN.

Specifications

- Vickers Hardness Testing Machine.

- With standard leaflet.

- Make : BIE, Model, BV-50.

- Load in KGF- 10,15, 15.625,

20,30,31.25, 40, 50.

Surface-Table – 2000x1000mm

Surface-Table – 2000x1000mm

Surface-Table – 2000x1000mm

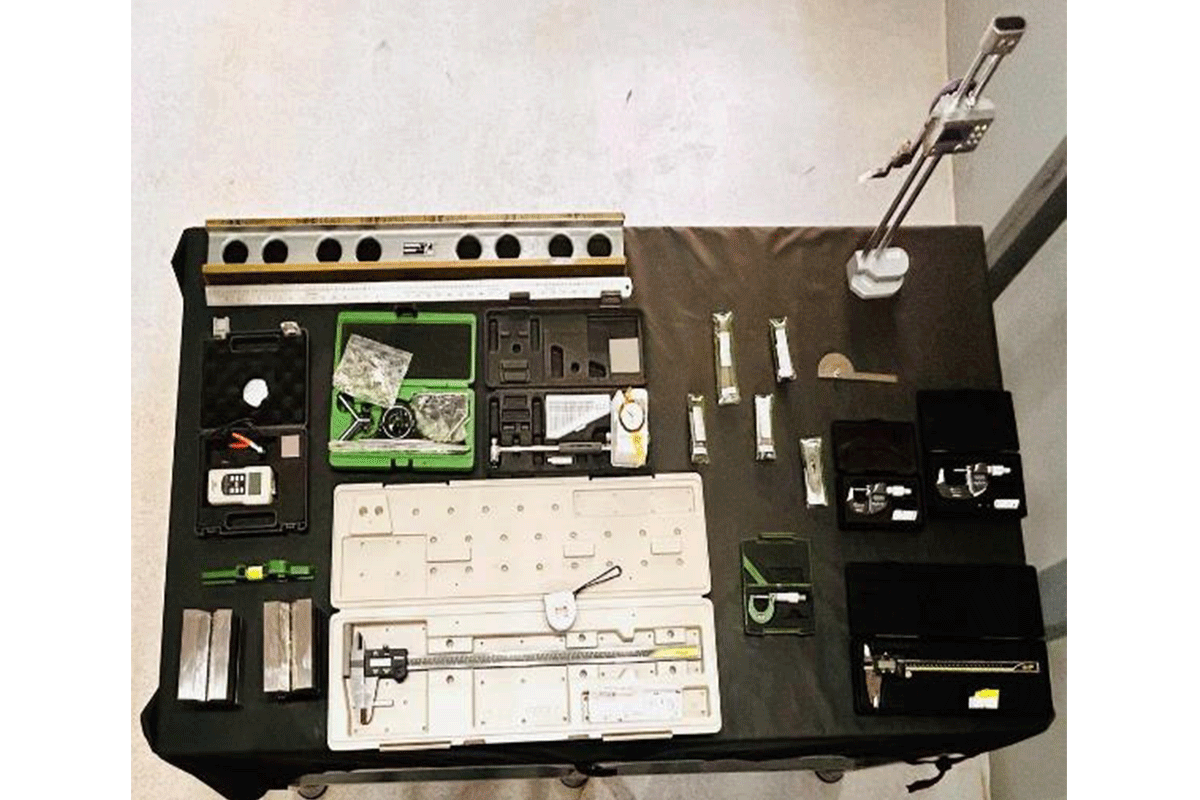

Measuring Instruments

Measuring Instruments

Various types of measuring instruments like Vernier’s, Outside micrometers, Height gauges, Filler gauges, Bore gauge sets, Slip gauge sets, DFT meters, etc are being used to ensure the quality of end products & control in process quality of the parts.